What Is Paint Breathability and Why Is It Important?

The term Breathability in the construction industry can sometimes be misleading. Although one would assume that it refers to the ability of the surface to allow the passage of air, it instead refers to the ability of the surface to allow water vapor to pass through.

As the building structure moves slightly due to thermal or mechanical effects, small hairline cracks inevitably open up and allow moisture to enter the structure. Typical acrylic paints are film formers that are like a plastic wrapping around the building trapping moisture. The trapped moisture can have deleterious effects on the structural integrity of the building through effects such as rebar corrosion, concrete ageing and ASR.

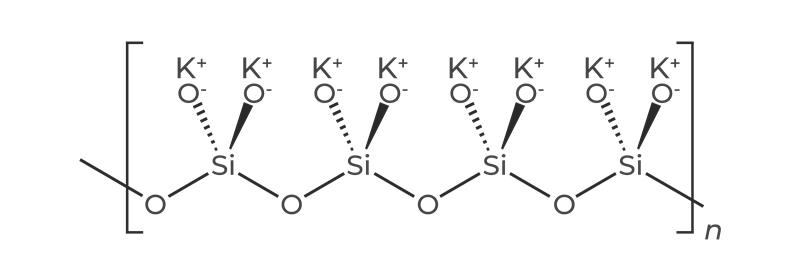

The steam diffusion coefficient, Sd, is considered one of the standard measurements of how easily moisture vapors are able to pass through a material. It is measured in meters and represents the resistance faced by the moisture in terms of equivalent distance of free air that it has to travel through to escape. Lower the Sd value, more breathable the paint is and vice versa. Typical acrylic paints have an Sd value between 0.5-1 and are not considered breathable. Silicate Mineral Paints on the other hand have an Sd values of 0.04 or less making them approximately 10 times more breathable than standard acrylic paints.

An ideal construction surface is one that repels liquid water yet allows trapped moisture to easily escape during the drying process. Zydex Silicate Mineral Paints form a microporous matrix where the pore sizes are small enough that surface tensions effects prevent liquid water from entering (See our article on “Wind Driven Rain Resistance of Silicate Mineral Paints”) but small enough to allow passage of vapor with an Sd value of < 0.03m. Thus, Zydex Silicate Mineral Paints help keep your building structures dry and prevent long term moisture damage.