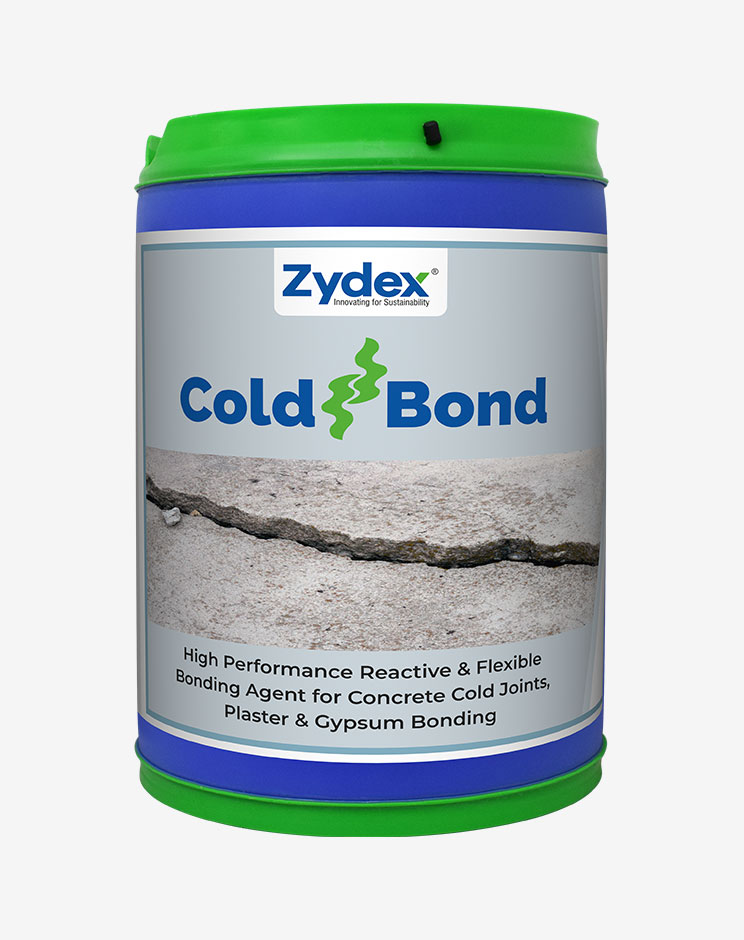

High-Performance Reactive & Flexible Bonding Agent

ColdBond is a next-generation acrylic-based bonding agent designed to provide superior adhesion and flexibility for concrete cold joints, plaster, and gypsum applications. Its innovative formulation ensures a durable, water-resistant, and monolithic bond that addresses common challenges in construction joints.

With a pull-off adhesion strength of 1.7 N/mm², ColdBond is ideal for creating long-lasting and crack-free structures.

Technical Specifications

| Property | Specification |

|---|---|

| Form | Translucent liquid dispersion |

| Specific Gravity | 1.0 to 1.2 |

| Solid Content | 35 ± 1% |

| Bulk Viscosity | < 200 cps |

| pH | 5.5 – 6.5 |

| Solubility (in Water) | Easily dispersible |

| Flash Point | Above 85°C |

| Particle Size | < 95 nm |

Key Features

- Reactive Bonding

Forms strong molecular-level bonds with concrete and plaster surfaces. - Monolithic Joints

Ensures a seamless and flexible connection between structures. - Highly Water-Resistant

Protects against seepage and leakage in bonded areas. - Exceptional Adhesion Strength

Offers a pull-off strength of 1.7 N/mm² for secure and durable joints. - Flexible Polymeric Film

Adapts to thermal cycling and shrinkage stresses, reducing the risk of cracks.

Challenges Addressed

Application Guidelines

Application Areas

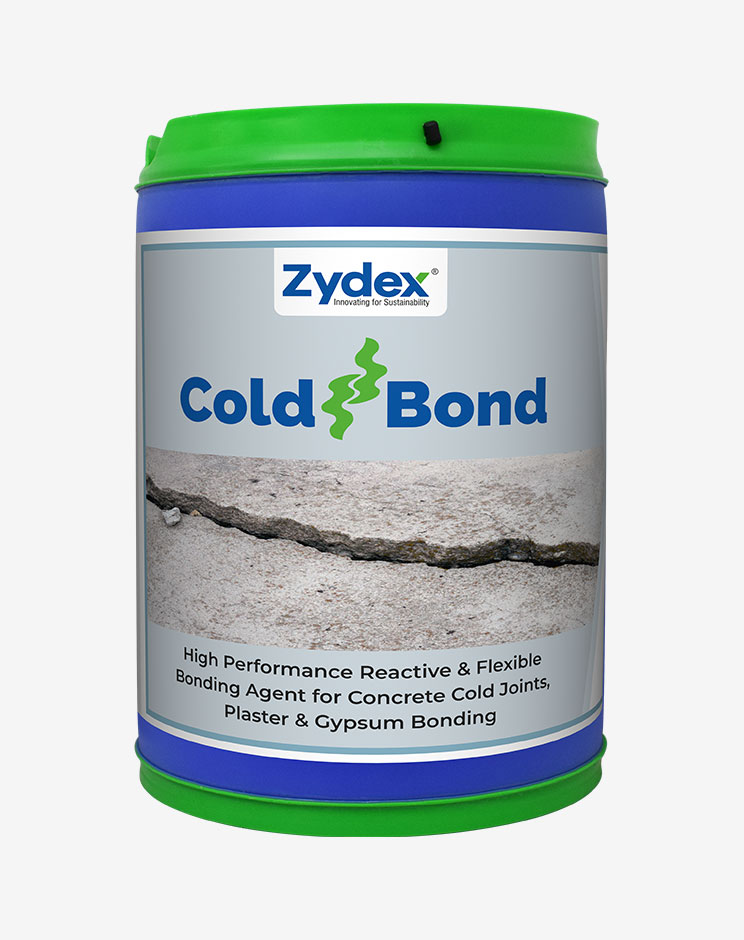

ColdBond is ideal for various jointing applications, including:

- RCC to PCC interfaces

- RCC to RCC joints

- RCC beams/columns to masonry walls

- RCC/PCC to plaster or gypsum interfaces

- Repair interfaces for PCC/plaster joints

- RCC/bricks to plaster connections

Dosage & Application Method

- Dilution

Use ColdBond undiluted or diluted 1:1 with potable water, depending on application needs. - Application

Apply using a brush, roller, or sprayer on concrete, plaster, gypsum, or brick surfaces. Ensure the brush or roller is soaked in water before use. - Application Window

Effective from 30 minutes to 72 hours post-application. - Important Note

Do not mix ColdBond with cement.

Coverage

- Undiluted: 40-50 ft² per litre

- Diluted (1:1): 80-100 ft² per litre (Coverage may vary based on surface conditions)

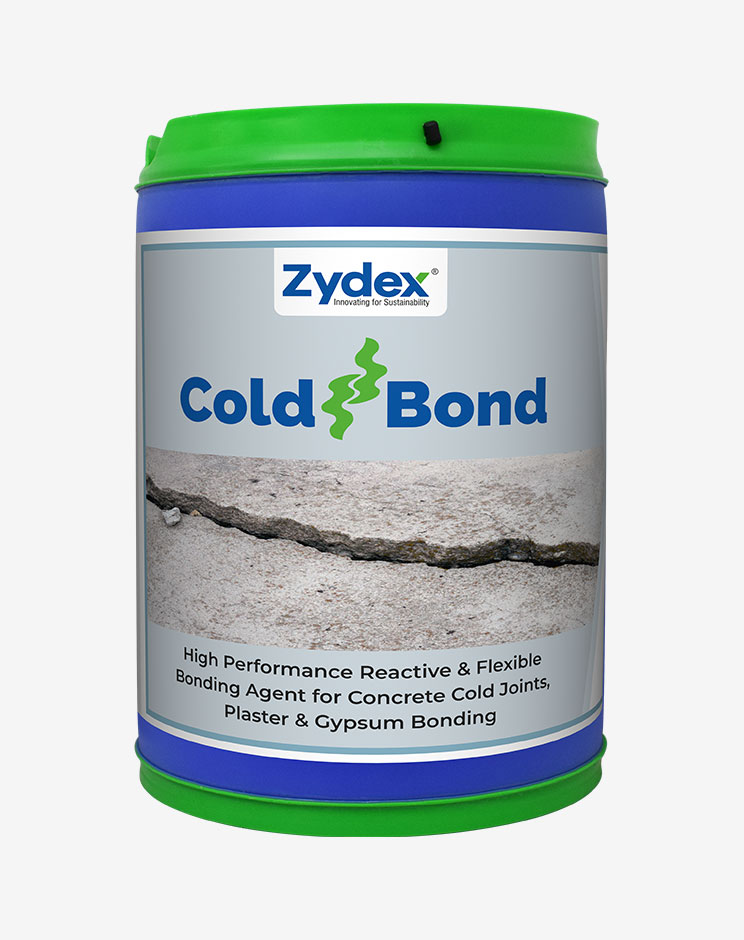

Packaging & Storing

Available in convenient sizes to meet various project requirements:

- 1 litre

- 5 litres

- 20 litres

- Storage Conditions: Store between +5°C and +45°C, away from direct sunlight.

- Shelf Life: Up to 4 years when stored as recommended.

Precautions

- Use ColdBond only as directed and avoid mixing with cement.

- Keep out of reach of children.

- In case of skin or eye contact, rinse thoroughly with water and seek medical advice if necessary.

ColdBond offers a groundbreaking solution for creating durable, water-resistant, and flexible joints in concrete and plaster applications. Explore its potential to elevate your construction quality today!